Air New Zealand is reviewing inspection procedures across its Airbus A320 fleet after a faulty fire switch caused an in-flight engine shutdown late last year, prompting an emergency landing in Auckland. Investigators say the defect may be more widespread than initially believed, with similar malfunctions reported on multiple A320-family aircraft worldwide.

The Transport Accident Investigation Commission (TAIC) confirmed that the incident occurred on Flight NZ249 in December 2024, operating from Wellington to Sydney, when the crew heard a loud clicking sound followed by an unexpected loss of thrust from the aircraft’s number two engine. The flight diverted safely to Auckland, where maintenance teams discovered that the engine fire switch — a cockpit safety mechanism designed to cut fuel flow and activate fire extinguishers — had engaged without any crew input.

According to the TAIC report, “similar faults have appeared across multiple aircraft, raising questions about how many units may be affected.” Investigators determined that neither pilot had touched the switch and that standard operating procedures did not require them to monitor the switch unless a fire warning was active.

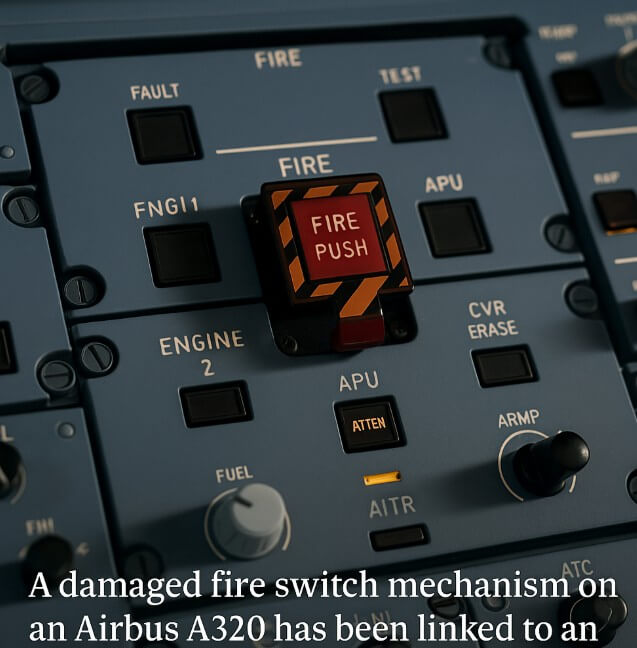

Post-incident inspections showed the fire switch was visibly protruding from its panel in the activated position, a finding consistent with other recent cases. The mechanism is intended to require deliberate manual engagement; however, damage inside the assembly made the switch susceptible to triggering on its own.

TAIC noted that the malfunction on NZ249 was “one of several cases where damaged or misaligned fire switches caused unintended activation.” To date, up to six known events have been linked to faulty or deformed switch assemblies across the A320 fleet.

Airbus later advised that comparable events had been documented on flights between Milan and Lisbon, as well as in earlier cases dating back to 2016. “All were linked to panel deformation and issues with pin-locking systems inside the switch assembly, RNZ reported.”

Internal Damage Traced to Deformed Components

Engineering teams examining the Air New Zealand aircraft found several structural issues surrounding the switch mechanism. TAIC reported that “the guard covering the Air New Zealand switch and the surrounding panel were bent out of shape,” while the retention pin designed to secure the mechanism “was also damaged and incorrectly positioned.” These defects increased the likelihood that the switch could “pop out” under vibration or normal aircraft movement.

Airbus had previously issued service bulletins covering 125 switch panels that had undergone repairs, recommending removal and inspection. Those bulletins focused on units showing external damage, but they did not account for internal misalignments that could lead to spontaneous activation.

In a further complication, investigators found that another A320 experienced the same issue even though its switch panel was not part of the bulletin-identified batch — broadening concerns about the true range of affected components.

Regulatory and Manufacturer Response

In the wake of the Air New Zealand incident, Airbus expanded its guidance to operators of all A320-family aircraft. The manufacturer called for inspections of any fire switch panel showing visible damage, classifying the work as a recommended action to be carried out within 1,000 flight cycles.

The European Union Aviation Safety Agency (EASA) subsequently issued a directive requiring that any damaged switch panel be replaced within six months, elevating the issue from a recommendation to a regulatory mandate.

New Zealand’s own civil aviation regulator has also expressed concern. The Civil Aviation Authority noted that “the true scope of the problem remained unclear,” prompting Air New Zealand to conduct fleetwide removals of suspect panels and request more detailed inspection standards from both manufacturers and maintenance providers.

Implications for the Global A320 Fleet

The Airbus A320 family is the world’s most widely used single-aisle jet, with more than 11,500 aircraft delivered. The widespread use of the type means any recurring component flaw — even one as small as a switch assembly — carries industry-wide significance.

The TAIC report adds that ongoing scrutiny of the A320 includes unrelated concerns, such as the effects of solar radiation on certain flight-control components. Together, these issues have reinforced the need for rigorous monitoring of component integrity as the fleet ages.

Investigators conclude that more work is needed to determine how many fire switches across the global A320 fleet may still harbor defects capable of triggering unintended activation. For airlines, regulators, and manufacturers, the findings underscore the importance of improving inspection regimes to prevent recurrence.

Stay tuned with us. Further, follow us on social media for the latest updates.